Decommissioning Fukushima / Discharge of Treated Water into Ocean Drawing Attention

K4 tank group for discharging treated water

14:02 JST, February 1, 2023

The Fukushima No. 1 nuclear power plant will soon mark the 12th anniversary of the unprecedented meltdown that resulted from the Great East Japan Earthquake and tsunami of March 11, 2011. The most pressing issue at present is the discharge of treated water into the ocean, as the on-site storage capacity is approaching its limit.

The government, during a ministerial meeting held on Jan. 13, projected that the discharge would begin in the spring or summer this year. However, local fishermen concerned about reputational damage and Pacific island nations are opposed to the ocean discharge.

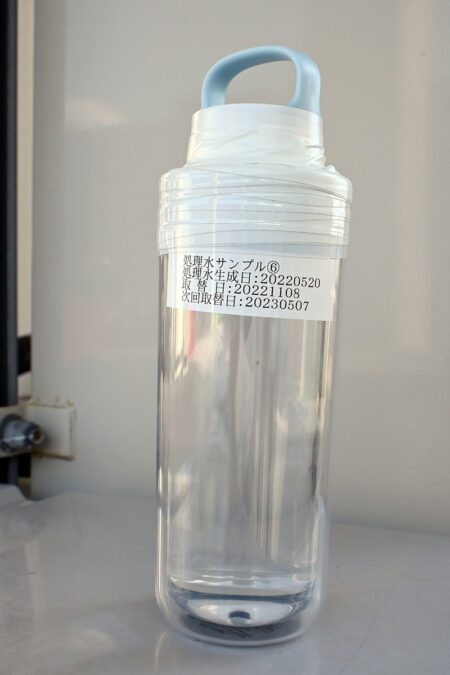

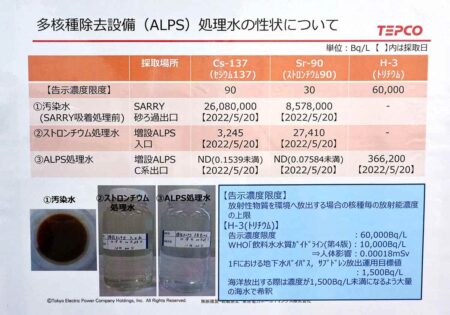

Treated water, according to Tokyo Electric Power Co. Holdings, is that which has been purified “until the concentration of radioactive materials, with the exception of tritium, falls well below regulatory standards for safety.”

To find out more, I visited TEPCO’s Fukushima No. 1 nuclear power plant, where decommissioning work is expected to take 30 to 40 years.

My visit on Jan. 26 was my first to the site in about 10 years. Compared to the last time, when it was stuffy being in protective clothing with a full face shield, I was surprised to find that I could move around most of the area with a helmet and disposable mask.

Subcontracted workers were busy here and there, and in the parking lot, vehicles that had been used to move within the premises after the accident were still parked there. The vehicles are no longer in use more than a decade after the accident, but because they are radioactive and cannot be disposed of normally, they remain on the site, having served their purpose.

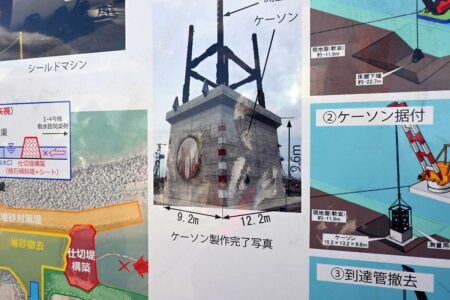

The four tips of a structure jut out of the sea. The water outlet is right beneath this point.

“It’s right over there,” said a TEPCO Holdings official, pointing offshore from the quay in front of reactors No. 5 and No. 6, which were spared from the accident.

Under a clear sky, I could see the four tips of a tower that jutted out of the sea. The tower is located 1 km offshore. The treated water will be discharged into the ocean through a water discharge outlet located on the seafloor approximately 12 meters undersea where the four tips are seen.

The installation of the water discharge outlet caisson has already been completed. Currently, work is underway to backfill the excavated seafloor around the outlet with concrete and mortar, and it is expected to be completed by the end of June.

“The days when the work can be done are limited due to severe sea conditions, such as waves and wind,” explained the official in charge at the site.

The shielded tunnel boring machine stopped excavating about 830 meters along the 1-km-long undersea tunnel to the water discharge outlet and is waiting for the connection from it.

-

The water intake tank almost in its final stage

-

The water intake tank

-

The water intake tank is on the right. At left is the discharge shaft under construction.

-

Equipment to remove driftwood, seaweed, fish and shellfish, etc. from pumped seawater before mixing with treated water

-

Machines used to move the shielded tunnel boring machine digging the undersea tunnel

-

Photo of the treated water outlet caisson

-

Photo of the shielded tunnel boring machine

Work is also progressing on the shore near the quay wall. Water tanks connecting to the tunnel were under construction. There are two tanks: the upstream tank, which is wide, and the adjacent downstream tank, which is about 16 meters deep. The upstream tank, divided by concrete walls that create channels, appeared to be almost complete, revealing its full extent. The system has been created so that treated water, diluted with seawater, enters the upstream tank, flows through the channels, then overflows into the downstream tank.

Once the discharge begins, TEPCO will directly confirm that the tritium concentration in the treated water has been diluted to below the target level through the mixing with seawater at this location, which can be considered the final point before the water is discharged.

Safety Considerations

K4 tanks are used for receiving, measuring/confirming, and discharging treated water on a rotating basis.

The Pacific Islands Forum, an organization of nearly 20 countries and regions including Australia and New Zealand, has called for a postponement of the ocean discharge. The PIF is of the opinion that the discharge into the ocean would have a significant negative impact on the fishing industry, given the lingering effects of past atomic bomb tests and other factors. China and South Korea have also expressed concern.

Local fishing cooperatives and other groups in Japan are also opposed. The government plans to seek their understanding by using funds totaling ¥80 billion set up to support the local fishing industry and to counter reputational damage.

Contaminated water is being generated at the Fukushima No. 1 nuclear plant because water is used to cool nuclear fuel that melted and solidified in reactor cores that were involved in the meltdown. This water is purified of 62 nuclides, including cesium and strontium, using an advanced liquid processing system (ALPS) and other equipment. However, since tritium cannot be removed by ALPS, it must be diluted with a large amount of seawater to a concentration of 1,500 becquerels per liter or less before being discharged into the ocean. Tritium is a radioactive isotope of hydrogen with three particles rather than the usual one.

Tritium produced from reactor operations is being released by nuclear power plants around the world. It does not arise only from plants that have experienced accidents.

Japan’s regulatory concentration limit for tritium in water is 60,000 becquerels per liter, and the World Health Organization’s drinking water standard guideline is 10,000 becquerels per liter. TEPCO’s aim for 1,500 becquerels per liter is 40 times more stringent than the national standard.

-

Treated water processed by ALPS is clear and colorless.

-

A graphic comparing contaminated and treated water shows contaminated water (lower left) is blackish.

-

Conceptual diagram of the circulation of cooling water of a nuclear reactor and the ALPS process

Moving to higher ground, 33.5 meters above sea level, I found a group of huge white tanks called K4. There are 35 such tanks with a capacity of 1,000 metric tons each. Thirty of these tanks, or 30,000 metric tons, are used to release treated water. From here, the treated water flows through transfer pipes toward the sea, being diluted with seawater along the way. The transfer pipes have two shutoff valves that stop the flow in the event of an earthquake, tsunami, or other emergency.

“Thirty tanks are divided into three groups of 10 tanks,” explained the TEPCO official. “Each group has a role of receiving, measuring/confirming, and discharging, and these roles are rotated.

“The treated water is stirred in the tanks to make it homogeneous, then the concentration of radioactive substances is measured,” the official added. “If it meets the government’s regulatory standards, it is discharged.”

From there, through further dilution with seawater, the treated water will have tritium concentrations at TEPCO’s stricter standard.

Measurements of the treated water are conducted by TEPCO and an outside inspection agency. TEPCO will disclose all such figures to the public and seek their understanding of the safety of the water.

Race Against Time

Storage tanks for treated water fill the southern part of the Fukushima No.1 nuclear power plant site.

Looking around the site from a window on the seventh floor of a large rest area, I saw a row of tanks lining the south side of the premises. These tanks store treated water. There are approximately 1,000 tanks, currently storing approximately 1.32 million cubic meters. The total capacity of the tank complex is 1.37 million cubic meters, which means that 96% of the tanks are already filled. Based on the calculation that 140 cubic meters of treated water is generated per day, the tanks will be full around this summer or autumn.

Why does this treated water continue to be generated in the first place? Inside the meltdown-affected reactors, fuel that melted and solidified is called fuel debris, which needs to be cooled by circulating water. Water that comes in contact with fuel debris becomes contaminated with radioactive substances. If this cooling water continues to be circulated without any increase in volume, there is no problem with using it in the reactor. The problem is that rainwater and groundwater continue to enter the damaged reactor buildings, causing a surplus of contaminated water. This excess contaminated water is processed by ALPS, generating treated water.

-

In the ALPS facility, the HIC, a special container that stores the slurry waste removed from the pre-processing step, is being exchanged for a new one.

-

Equipment to remove magnesium ions, calcium ions, etc. prior to ALPS processing

-

ALPS equipment that removes various radioactive substances by adsorbing them onto a filter.

-

The HIC container that has been exchanged is transported by a trailer to a storage area within the site.

Initially, about 540 cubic meters of treated water was generated per day, meaning one tank was filled in two days. Later, the amount was reduced to 130 cubic meters per day in fiscal 2021 through the use of facings to prevent rainwater from seeping into the ground and by building an ice wall underground to surround the building to reduce the amount of groundwater flowing in. Last year, when only June and October had much rain, the amount was below 100 cubic meters per day.

The discharge of treated water into the ocean, however, would have to be greater than the amount generated in a single day to decrease the overall amount. So how much is planned to be released per day? According to calculations based on the performance of the seawater pumps, 500 cubic meters per day could be released.

The TEPCO official denied this, saying, “That will never happen.”

He explained: “It will take time to measure radioactive substances before the discharge. We have received comments from various parties that it would be better to take our time and release the water in a way that would have as little impact or cause as little change as possible.”

TEPCO plans to gradually reduce the treated water over the next several decades during the decommissioning period.

Ensuring safety, making public disclosures, and gaining domestic and international understanding of the oceanic release: The decommissioning of the Fukushima No. 1 nuclear power plant is approaching one of its climaxes this year, with a great many difficult challenges ahead.

Japanese version

福島原発「処理水」の海洋放出、迫るタイムリミット…廃炉の現場ルポ

Top Articles in JN Specialities

-

Exhibition Shows Keene’s Interactions with Showa-Era Writers in Tokyo, Features Newspaper Columns, Related Materials

-

The Japan News / Weekly Edition (2/20-2/26)

-

Step Back in Time at Historical Estate Renovated into a Commercial Complex in Tokyo

-

The Japan News / Weekly Edition (1/30-2/5)

-

Prevent Accidents When Removing Snow from Roofs; Always Use Proper Gear and Follow Safety Precautions

JN ACCESS RANKING

-

Japan PM Takaichi’s Cabinet Resigns en Masse

-

Japan Institute to Use Domestic Commercial Optical Lattice Clock to Set Japan Standard Time

-

Israeli Ambassador to Japan Speaks about Japan’s Role in the Reconstruction of Gaza

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo Station

-

Videos Plagiarized, Reposted with False Subtitles Claiming ‘Ryukyu Belongs to China’; Anti-China False Information Also Posted in Japan