Hokkaido Gov. Naomichi Suzuki, left, and Rapidus President Atsuyoshi Koike at the Hokkaido prefectural government office in Sapporo on Monday.

21:00 JST, March 2, 2023

Chipmaker Rapidus Corp. has selected Chitose, Hokkaido, as the proposed site for a factory but is expected to face a number of challenges on the way to achieving mass production.

Aiming to domestically produce next-generation semiconductors, Rapidus decided to build a plant in Chitose after receiving approval for government subsidies and other measures. The company intends to start full-scale preparations for the start of mass production in 2027.

Competition to win project

“We will build an unprecedented semiconductor plant that will astonish the world,” Rapidus President Atsuyoshi Koike told the press on Monday after a meeting with Hokkaido Gov. Naomichi Suzuki at the Hokkaido prefectural government office.

The Tokyo-based newly created chipmaker selected Chitose because it has water resources essential for semiconductor production and convenient transportation. The industrial complex is only a five-minute drive from New Chitose Airport, with smooth connections to an expressway and a rail line to Sapporo. Several municipalities competed behind the scenes to bring in the factory, according to a source close to the project.

Rapidus was established last summer and is funded by eight Japanese companies, including Toyota Motor Corp. and NTT Corp.

The goal is to produce the most advanced semiconductors, known as the 2-nanometer generation, which are expected to become the brains of artificial intelligence and supercomputers. However, production technology for these semiconductors has not yet been devised.

‘Last chance’

Taiwan Semiconductor Manufacturing Company (TSMC) leads the world in semiconductor manufacturing, while Japan relies on overseas procurement for almost all of its advanced semiconductors.

Semiconductors are becoming increasingly important from the perspective of economic security. In June 2021, the government said it would “tackle [the semiconductor issue] as a national strategy” and support Rapidus’ initiatives through subsidies and other means.

“This will be the last chance for Japan to work on cutting-edge semiconductor products,” a source close to the project said.

Rapidus has no expertise in manufacturing advanced semiconductors, and will collaborate with IBM Corp. of the United States and imec (Interuniversity Microelectronics Centre), a Belgian research and development organization, to dispatch researchers and other personnel to learn the technology.

“This is a symbolic project of Japan-U.S. collaboration, and I welcome its progress. The government will provide the necessary support,” Economy, Trade and Industry Minister Yasutoshi Nishimura said at a press conference on Monday.

Problems remain

However, there are still many issues to tackle.

Producing advanced semiconductors requires microscopic processing, which will need an investment of ¥2 trillion to establish the technology and ¥3 trillion to prepare the mass production line.

Nearly 1,000 engineers must also be recruited for the production line before it is ready to go into operation.

Koike said only that he would explain the financing plan once the firm had a clear prospect for fundraising.

Even if Rapidus successfully begins operation, it is essential to continue to invest in the development of new technologies that are evolving day by day.

Semiconductors are subject to repeated boom-bust cycles, known as the silicon cycle, and it is difficult to predict whether the company will be able to meet customer demand after it starts operations.

“Rapidus’ project will flounder unless the companies that use the semiconductors, including those that have invested in Rapidus, draw up a strategy for what kind of products they will create using the cutting-edge semiconductors,” Meisei University Prof. Masahiko Hosokawa said.

Top Articles in Business

-

Prudential Life Insurance Plans to Fully Compensate for Damages Caused by Fraudulent Actions Without Waiting for Third-Party Committee Review

-

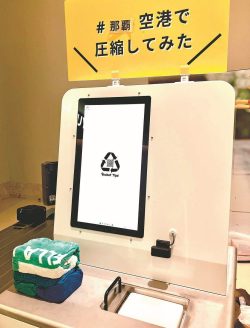

Narita Airport, Startup in Japan Demonstrate Machine to Compress Clothes for Tourists to Prevent People from Abandoning Suitcases

-

Japan, U.S. Name 3 Inaugural Investment Projects; Reached Agreement After Considerable Difficulty

-

Toyota Motor Group Firm to Sell Clean Energy Greenhouses for Strawberries

-

SoftBank Launches AI Service for Call Centers That Converts Harsh Customer Voices into Softer Voices

JN ACCESS RANKING

-

Japan PM Takaichi’s Cabinet Resigns en Masse

-

Japan Institute to Use Domestic Commercial Optical Lattice Clock to Set Japan Standard Time

-

Israeli Ambassador to Japan Speaks about Japan’s Role in the Reconstruction of Gaza

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo Station

-

Videos Plagiarized, Reposted with False Subtitles Claiming ‘Ryukyu Belongs to China’; Anti-China False Information Also Posted in Japan