The Art of Making ‘Japan Blue’; Founded in 1914, Nogawa Senshoku Kogyo Continues Making Dye for Popular Color Using Traditional Techniques

A craftsman soaks bundles of thread in dye beneath the floorboards, where they gradually take on rich indigo hues.

16:29 JST, December 15, 2025

An exterior view of Nogawa Senshoku Kogyo’s head office and factory

HANYU, Saitama — Thirteen jars of indigo dye are lined up beneath the factory floor. Each jar contains dye that has undergone a different fermentation period and varies in dyeing strength.

An artisan steadily and quietly repeats the task of dipping bundles of thread into the jars at his feet and pulling them back up. “I’m proceeding with the work while carefully examining the dyeing degree and color tone to ensure the indigo permeates every corner,” he said.

A worker sews fabrics made from dyed threads with a sewing machine.

The area of Hanyu in Saitama Prefecture is said to have been renowned for indigo dyeing since the Edo period (1603-1867), producing work clothes for farmers. In 2008, the dyeing method in the area was trademarked as “Bushu Sho Aizome,” or Bushu area’s true indigo dyeing. Founded in 1914, Nogawa Senshoku Kogyo continues to use these traditional techniques.

The dye is made from sukumo (naturally fermented indigo leaves), fusuma (wheat husks) and lime, and does not contain any chemical dyes. When the bundles of dyed thread are lifted out, the pigment reacts with the oxygen in the air and turns indigo blue. The simple, deep hues created by the varying shades of indigo are called “Japan Blue” and are popular overseas.

A store owned by Nogawa Senshoku Kogyo near the head office sells indigo-dyed goods.

Another notable aspect of the method is the “pre-dyeing” process, in which the threads are dyed before weaving, rather than afterward. “The dye coating increases the threads’ strength, and hand-dyeing creates a unique striped pattern on the fabric called Aojima (blue stripes),” said Yuki Nogawa, 35, managing director of the firm, explaining the appeal of the dyeing method.

A kendo uniform called Bushu ichi, which is made with fabric that offers both suppleness and strength, is the company’s highly regarded original brand. When sales of kendo uniforms plummeted in 2020 due to the coronavirus pandemic, the firm seized the opportunity to diversify its product line. It developed indigo-dyed masks, slippers and other items, overcoming the crisis. The firm now offers hundreds of products, including bedding, dresses and stoles.

Hundreds of indigo dyeing workshops are said to have once operated in the area around Hanyu. Today, however, the city only has three. Nogawa reaffirms his resolve to preserve the local industry.

“While preserving traditional techniques, we aim to continue developing products closely tied to daily life,” he said.

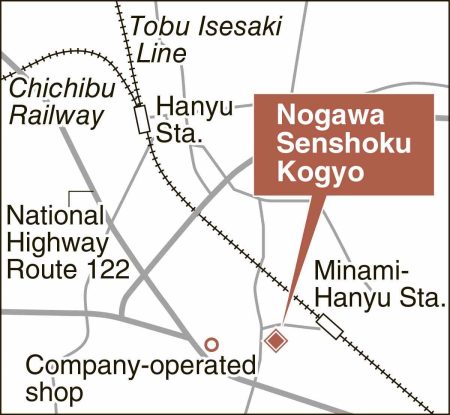

Nogawa Senshoku Kogyo

Address: 878 Sukage, Hanyu, Saitama Prefecture. The company-owned shop, which sells indigo-dyed products, is in 471-4 Sukage, Hanyu.

Access: The shop is five minutes by car from Hanyu Station on the Tobu Isesaki Line or a 25-minute walk from Minami-Hanyu Station on the same line.

Hours:The shop is open from 10:30 a.m. to 6 p.m. from Friday to Sunday. It also has an online store.

Related Tags

Top Articles in Features

-

Sapporo Snow Festival Opens with 210 Snow and Ice Sculptures at 3 Venues in Hokkaido, Features Huge Dogu

-

Tokyo’s New Record-Breaking Fountain Named ‘Tokyo Aqua Symphony’

-

Tourists Flock to Ice Dome Lodge at Resort in Hokkaido, Japan; Facility Invites Visitors to Sleep on Beds Made of Ice

-

High-Hydration Bread on the Rise, Seeing Increase in Specialty Shops, Recipe Searches

-

Heirs to Kyoto Talent: Craftsman Works to Keep Tradition of ‘Kinran’ Brocade Alive Through Initiatives, New Creations

JN ACCESS RANKING

-

Japan PM Takaichi’s Cabinet Resigns en Masse

-

Japan Institute to Use Domestic Commercial Optical Lattice Clock to Set Japan Standard Time

-

Israeli Ambassador to Japan Speaks about Japan’s Role in the Reconstruction of Gaza

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo Station

-

Man Infected with Measles May Have Come in Contact with Many People in Tokyo, Went to Store, Restaurant Around When Symptoms Emerged