Satoko Koda weaves using a seasoned loom.

14:00 JST, February 15, 2026

A hakama garment made of high-grade Sendaihira silk fabric elegantly billows when seated and falls straight and smoothly when standing. Once, it was worn by Nobel laureate Yasunari Kawabata, and recently by People’s Honor Award-winning figure skater Yuzuru Hanyu at their respective award ceremonies.

The origins of the textile are said to date to the Edo period (1603-1867) when Date Tsunamura, fourth lord of the Sendai domain, hired a weaver and had him produce textiles for the domain. It became a local specialty, and six private companies in Sendai continued to produce it after the Meiji era (1868-1912). Today only one remains: A joint-stock company called Sendaihira & Co., with its workshop standing by the banks of the clear Hirose River.

Satoko Koda, 61, the company’s representative and sole weaver, is the fifth generation owner. She is proud of the “one and only” hakama textile, and said, “[It] makes any movement look beautiful and shiny.”

“It brings out an indescribable charm in a man wearing hakama,” she added. The process involves 30 steps, starting with refining raw silk to soften it and dyeing it with plant-based dyes.

On the seasoned loom, 10,000 warp threads in various colors were arranged. For complex patterns like gradients, arranging each thread individually can take one month. For the weft threads, a dozen or so strands finer than hair are gathered without twisting, moistened with water, and combined into one.

Warp threads of various colors arranged on a loom

The weaver steps on the treadle to pass the weft thread through the warp threads, then firmly strikes it three times. This method creates a unique texture with softness vertically and firmness horizontally.

Weaving one bolt, about 11 meters, takes over two to three weeks. “It’s endless work,” Satoko said. “It feels like walking a little bit all day long. If only I could do it without sleeping.”

Her focused movements of hands and feet evoke the folk tale “The Grateful Crane.”

“I think I understand why the crane grew so thin and frail,” she said.

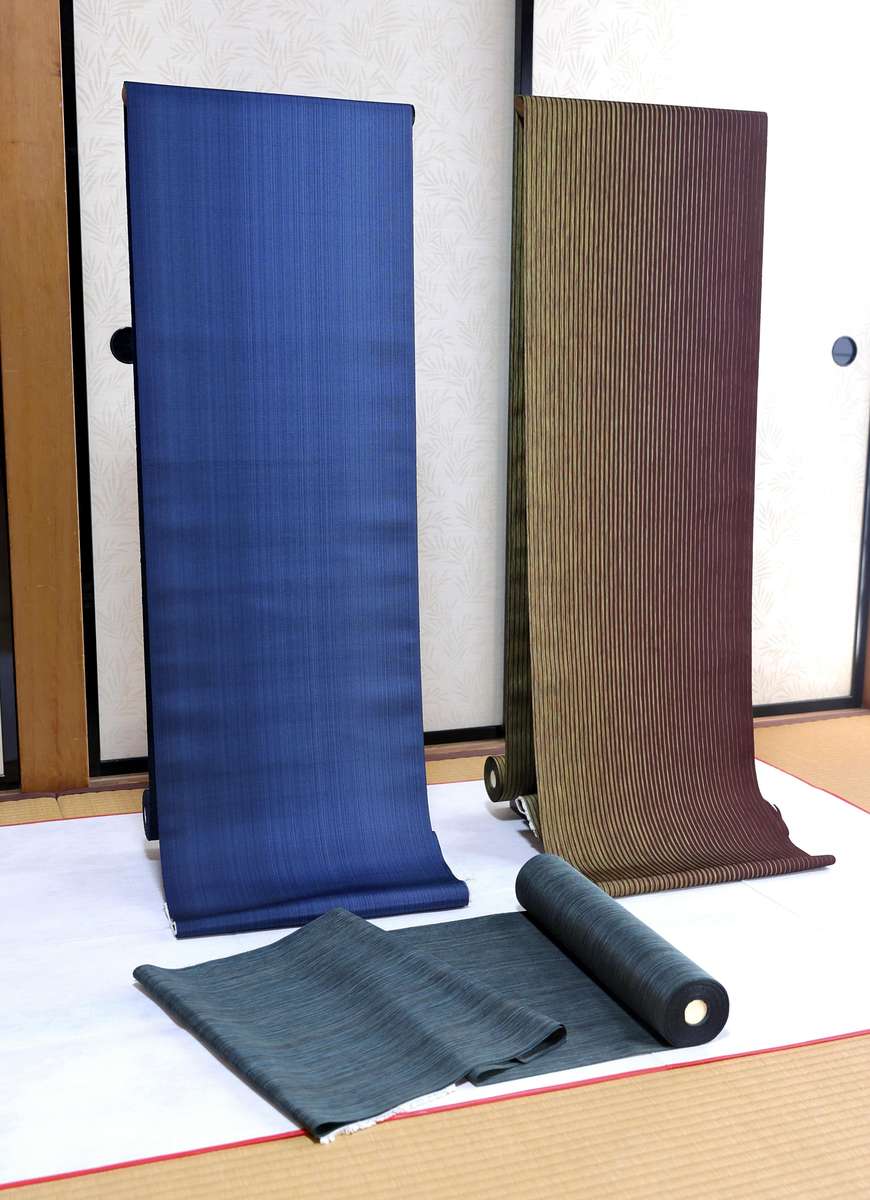

Sendaihira bolts of fabric

This technique, passed down through a single lineage, is designated an important intangible cultural heritage asset. Her grandfather, Eisuke, and father, Yoshio, were both living national treasures. Even when forced to switch to producing military uniforms and supplies during the war, and despite the rapid shift toward Western-style clothing after the war, Eisuke continued researching and improving traditional refining and dyeing techniques.

“My father always stood by my grandfather’s side. After my grandfather passed, he worked alone tirelessly — I watched him do it all,” said Satoko. Though she majored in English and American literature in university, she made a serious request upon graduation, saying, “Please teach me in earnest. I’ll commit myself fully.”

She laughed and said, “I showed my respect in my own way.” As the heir to the tradition, it was only seven years ago that she felt she had finally gotten her own start when her father permitted her to exhibit at the Japan Traditional Kogei Exhibition.

Yoshio, who had walked this path alongside Satoko, passed away last October at the age of 96.

Her husband Masaki, 63, who shares responsibilities like dyeing raw silk, smiled as he recalled, “Toward the end, whenever something came up, ‘Ask Satoko’ was President Yoshio’s catchphrase.”

“Maybe he was acknowledging me a little,” said Satoko. “[But] there’s still much to do before passing the baton to the next generation.

Related Tags

Top Articles in Culture

-

Director Naomi Kawase’s New Film Explores Heart Transplants in Japan, Production Involved Real Patients, Families

-

Tokyo Exhibition Offers Inside Look at Impressionism; 70 of 100 Works on ‘Interiors’ by Monet, Others on Loan from Paris

-

Exhibition Featuring Yoshiharu Tsuge’s Manga World Underway in Chofu, Tokyo; Unique, Surreal Works Draw Steady Crowds

-

2 Unpublished Early Novellas by Japan’s Kenzaburo Oe Discovered, Show Budding Promise of Future Nobel Prize-Winning Author

-

Japanese Film, Anymart, Wins Critics’ Award at International Film Festival in Berlin, Director’s Debut Feature Film Shocks Audiences

JN ACCESS RANKING

-

Producer Behind Pop Group XG Arrested for Cocaine Possession

-

Japan PM Takaichi’s Cabinet Resigns en Masse

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo Station

-

Videos Plagiarized, Reposted with False Subtitles Claiming ‘Ryukyu Belongs to China’; Anti-China False Information Also Posted in Japan

-

Prudential Life Insurance Plans to Fully Compensate for Damages Caused by Fraudulent Actions Without Waiting for Third-Party Committee Review