A test furnace for the hydrogen reduction steelmaking technology

November 18, 2021

Following the conclusion of the U.N. climate summit, where measures to combat climate change were center stage, nations will likely face various challenges associated with such efforts going forward. This series will explore what a future decarbonized society might look like based on initiatives being rolled out around the world.

Poland’s Belchatow power plant, the largest coal-fired power plant in Europe, generates about 20% of the electricity consumed in the country.

In June, the company that owns the power station announced that by the end of 2036 it would close the plant, which is located in the middle of a forest on the outskirts of Belchatow, a city about 150 kilometers from Warsaw.

In coal-rich Poland, coal-fired power accounts for 70% of all electricity generated — the highest ratio among the 27 EU member states.

In February, the Polish government announced that it would introduce renewable energy sources and nuclear power plants in areas where coal is a key industry, with plans to invest an amount equivalent to ¥1.7 trillion.

About 100,000 people work in Poland’s coal industry, with about 10,000 people involved in jobs linked to the Belchatow power plant, including those working in nearby coal mines.

The company intends to gradually reduce the number of employees as workers reach retirement age.

“I’m worried about jobs for young people,” said a 72-year-old who worked at the power plant and in the mines for 25 years. “After the plant is closed, there will be no reason for them to stay in the region.”

During the 26th session of the Conference of the Parties to the U.N. Framework Convention on Climate Change (COP26), a statement committing to shift away from coal power generation was signed by 46 countries and regions, including Poland.

Britain, which chaired the conference, had originally called for advanced countries to end coal power by 2030 and for other countries by 2040. However, these targets were softened in the Nov. 4 statement to “the 2030s” and “the 2040s,” respectively.

Bearing in mind Poland is not a member of the Group of Seven industrialized nations or the Group of 20 advanced and emerging economies, Adam Guibourge-Czetwertynski, Poland’s deputy minister of climate and environment, told The Yomiuri Shimbun that the situation will vary from country to country.

Although the statement is not legally binding, Poland is expected to aim to end all coal power generation by the late 2040s.

The electricity and heat production sector, which includes coal, is a large source of greenhouse gas emissions, along with the transportation sector.

China depends on coal for more than 60% of its power generation and India for more than 70%. Japan relies on coal for about 30% of its power generation.

Japan, the United States, China and India did not sign the Nov. 4 statement.

The Glasgow Climate Pact was adopted at COP26 on Saturday. While an earlier draft used the expression “phase-out” regarding coal power, the language was softened and revised to “phasedown” at the last minute, because of objections from China and India, both of which are highly dependent on coal.

At a press conference Sunday held after the closing of the climate summit, COP26 President Alok Sharma failed to hide his frustration. “In terms of China and India, they will on this particular issue have to explain themselves to developing countries,” he said, as climate change is most seriously felt by such countries.

The accessibility of energy sources varies from country to country and region to region, whether the issue is fossil fuels such as coal and natural gas, renewable energy or nuclear power. The question is how to move toward the common goal of realizing a decarbonized society, and how to find a realistic solution based on the different situations in each country.

Industries’ burden

The shift toward a coal-free economy presents a heavy challenge to Japan’s manufacturing industry.

A trial of a steelmaking technology that utilizes hydrogen has been underway since 2013 at East Nippon Works Kimitsu Area in Kimitsu, Chiba Prefecture, the core facility of Japan’s largest steel company Nippon Steel Corp.

A test furnace jointly developed with the New Energy and Industrial Technology Development Organization (NEDO) and others is located in an enclosed area surrounded by 20-meter-high metallic walls. To prevent the outflow of technology, even people involved in the project are strictly restricted from accessing the area. According to an industry source, the technology could change the 150-year history of modern steelmaking.

The basic process of steelmaking involves mixing coal and iron ore at very high temperatures, which produces a large amount of carbon dioxide. But in so-called hydrogen reduction steelmaking, iron ore is reacted with hydrogen and only water is discharged.

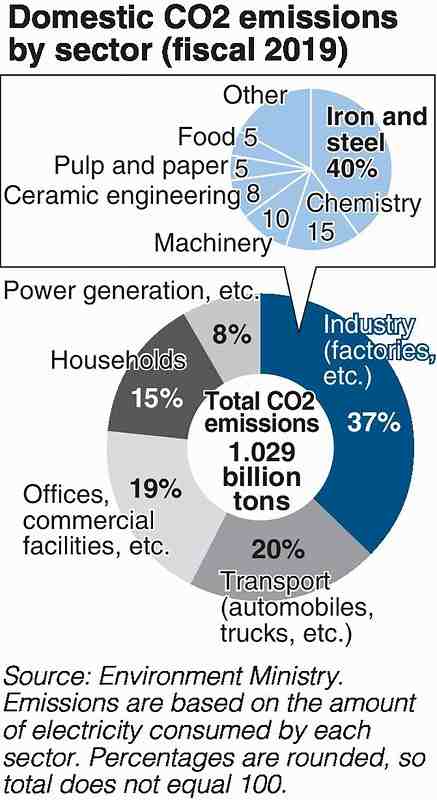

The iron and steel industry accounts for 40% of carbon dioxide emissions generated by the industry sector in Japan.

Hydrogen reduction steelmaking technology is expected to be a key asset in the industry to reduce emissions. However, commercialization of the technology does not appear to be close.

The test furnace has succeeded in cutting carbon dioxide emissions by just 10%. With conventional furnaces, it is possible to reuse heat generated in the steelmaking process to generate power at the plants, but with hydrogen reduction steelmaking, heat is lost during the reaction so plants have to secure other power sources.

It is said that it costs ¥1 trillion to construct a conventional furnace.

Nippon Steel estimates the research and development cost of the new technology at ¥500 billion and the cost of renewing facilities at ¥4 or ¥5 trillion.

The company plans to raise steel prices and ask its suppliers and consumers to bear part of the cost, but it is uncertain whether it will gain their understanding.

The company might be reluctant to invest a huge amount of money as the main objective of the project — decarbonization — is not directly related to the improvement of its products.

The demand for steel products such as electromagnetic steel sheets used in electric vehicle motors and the basic structures of wind turbines for wind power generation is likely to increase worldwide.

The huge costs involved in the shift away from coal might give competitors an edge in terms of price.

“We should obtain public understanding first and then create a system that allows society as a whole to bear the cost,” said Eiji Hashimoto, chairman of the Japan Iron and Steel Federation and president of Nippon Steel.

The government is considering creating a system to make it easier for financial institutions to fund the development of new technologies, among other issues.

How should funds be raised to pay for the transition to a decarbonized society? A road map is needed as soon as possible.

Top Articles in Business

-

Prudential Life Insurance Plans to Fully Compensate for Damages Caused by Fraudulent Actions Without Waiting for Third-Party Committee Review

-

Narita Airport, Startup in Japan Demonstrate Machine to Compress Clothes for Tourists to Prevent People from Abandoning Suitcases

-

Japan, U.S. Name 3 Inaugural Investment Projects; Reached Agreement After Considerable Difficulty

-

JR Tokai, Shizuoka Pref. Agree on Water Resources for Maglev Train Construction

-

Toyota Motor Group Firm to Sell Clean Energy Greenhouses for Strawberries

JN ACCESS RANKING

-

Japan PM Takaichi’s Cabinet Resigns en Masse

-

Japan Institute to Use Domestic Commercial Optical Lattice Clock to Set Japan Standard Time

-

Israeli Ambassador to Japan Speaks about Japan’s Role in the Reconstruction of Gaza

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo Station

-

Videos Plagiarized, Reposted with False Subtitles Claiming ‘Ryukyu Belongs to China’; Anti-China False Information Also Posted in Japan