14:59 JST, June 10, 2024

The auto industry has many problems in addition to the issue of fraudulent applications for model certification, which is required for mass production.

The nature of one of the industry’s deep-rooted problems, in which only small and midsize companies are affected by cost cutting efforts in response to high prices, must be changed.

The Japan Fair Trade Commission admonished Nissan Motor Co. on March 7, saying the automaker violated the Subcontract Law in lowering the prices it paid for auto parts from contractors after orders were placed. The admonishment demanded Nissan prevent similar incidents, among other measures.

As there were reports that improper transactions continued after the admonishment, Nissan announced the results of its own investigation at the end of last month. Although the company stated that no violations of the law were found, Nissan President Makoto Uchida said at a press conference, “It is true that our business partners have been voicing increased dissatisfaction.”

Nissan said it will set up an organization under the direct control of the president to thoroughly respond to its business partners.

A structural problem lies behind the strong dissatisfaction among small and midsize companies in Japan’s auto industry. Major companies, which boast of their competitiveness, have grown together with their contractors, requesting cost reductions from them in exchange for guaranteeing long-term business relationships.

However, since the COVID-19 pandemic, inflation has grown due to soaring energy prices and other factors, and small and midsize companies are struggling to pass on increased costs in their prices when dealing with large client companies.

In 2021, the JFTC found Mazda Motor Corp. to have violated the law. The commission disclosed the names of Denso Corp., a major auto parts manufacturer in the Toyota group, in 2022 and Daihatsu Motor Co. and others this year as companies having problematic dealings with their contractors.

The auto industry is a core industry, and together with related businesses, it employs about 5.5 million people. It should take the initiative in improving business dealings with contractors.

The Japan Automobile Manufacturers Association, an industry group, will submit the results of its inspection by the end of June and report whether there are any violations of the Subcontract Law. Issues should be thoroughly identified.

Due to the string of problems, the association has revised its voluntary action plan to ensure appropriate business dealings. Under the plan, automakers will reportedly allow suppliers to pass on an appropriate level of increased energy and raw material costs in their prices for their clients.

The Japanese economy is at a turning point, headed toward a complete exit from deflation. Toyota’s profit for the business year ended March 2024 was nearly ¥5 trillion, and Honda Motor Co.’s exceeded ¥1 trillion. It is important for major auto companies to allow an appropriate level of costs to be passed on and to enhance the capacity of small and midsize companies to raise wages.

The problem of passing the buck to contractors is not limited to the automobile industry. The logistics industry, for example, is said to have particular difficulty in passing on costs. The government and the JFTC should strengthen their monitoring of industries.

(From The Yomiuri Shimbun, June 9, 2024)

Top Articles in Editorial & Columns

-

Riku-Ryu Pair Wins Gold Medal: Their Strong Bond Leads to Major Comeback Victory

-

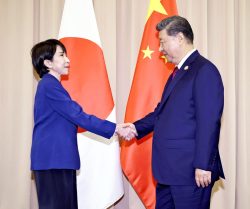

China Provoked Takaichi into Risky Move of Dissolving House of Representatives, But It’s a Gamble She Just Might Win

-

University of Tokyo Professor Arrested: Serious Lack of Ethical Sense, Failure of Institutional Governance

-

Reciprocal Tariffs Ruled Illegal: Judiciary Would Not Tolerate President’s High-Handed Approach

-

Japan’s Plan for Investment in U.S.: Aim for Mutual Development by Ensuring Profitability

JN ACCESS RANKING

-

Japan PM Takaichi’s Cabinet Resigns en Masse

-

Japan Institute to Use Domestic Commercial Optical Lattice Clock to Set Japan Standard Time

-

Israeli Ambassador to Japan Speaks about Japan’s Role in the Reconstruction of Gaza

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo Station

-

Videos Plagiarized, Reposted with False Subtitles Claiming ‘Ryukyu Belongs to China’; Anti-China False Information Also Posted in Japan