Japan’s Steelmakers Turn to Hydrogen in Decarbonization Efforts, but High Costs Hinder Progress

A blast furnace is seen at East Nippon Works Kimitsu Area in Chiba Prefecture, where Nippon Steel will conduct test for iron reduction with hydrogen next year.

21:00 JST, December 8, 2025

Major Japanese steel companies are conducting tests utilizing hydrogen in the extraction of iron from iron ore in the pursuit of decarbonization.

Steelmakers are working to establish so-called green steel manufacturing technologies, but developing the technologies and realizing mass production would significantly increase costs, presenting high hurdles to full-scale implementation.

The mainstream method of steelmaking involves putting iron ore and coke into a blast furnace operating at high temperatures. The oxygen is separated from the iron in a reduction reaction, and large amounts of carbon dioxide are also generated. The steel industry accounts for 13% of Japan’s total CO2 emissions.

The replacement of blast furnaces with electric furnaces, which reduce emissions by about 75%, is progressing. However, because scrap iron is used as a raw material, impurities are mixed into the final product, affecting quality and making it unsuitable for creating high-end products such as those used in automobiles.

Moreover, electric furnaces incur high electricity costs, making it economically unrealistic to convert to them entirely. For this reason, major steelmakers are focusing on the use of hydrogen, which does not produce CO2 when it reacts with iron oxide.

World-leading results

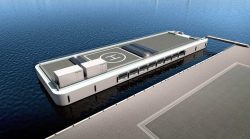

Nippon Steel Corp. will begin demonstrating reduction reactions using hydrogen in blast furnaces at its plant in Kimitsu, Chiba Prefecture, next year. replacing some of the coke used with hydrogen.

In a reduction experiment using a small test furnace, the company succeeded in cutting CO2 emissions by 43%, a world-leading figure. Through the experiments, an issue was revealed: using hydrogen results in an endothermic reaction — one that absorbs heat — causing the temperature inside the blast furnace to drop and hindering the reduction process. The company overcame this issue by developing a system to inject heated hydrogen.

JFE Steel Corp. is conducting research into a carbon-recycling blast furnace, which adds hydrogen to CO2 emitted from the furnace to produce methane, which is then fed back into the furnace as a reducing agent along with coke. The company claims this will reduce CO2 emissions by more than 50% compared to conventional blast furnaces. A two-year demonstration project began in May at a small-scale blast furnace at the steelworks in Chiba City.

Kobe Steel Ltd. has already established a process using hydrogen direct reduction, which involves replacing coke as the reducing agent with hydrogen to produce a semi-finished iron product, which is then put back into the blast furnace together with iron ore and coke to produce the final product. The technology is said to lead to a 20%-40% reduction in CO2 emissions.

High costs discourage investment

High costs are a major obstacle to introducing CO2 reduction methods in steelmaking. According to a Kobe Steel official, costs will be at least double those of conventional methods.

As market conditions worsen due to shrinking domestic demand and overproduction in China, there have been moves to reconsider decarbonization investments. Kobe Steel had planned to invest ¥300 billion in decarbonization-related projects over three years from fiscal 2024, including the expanded use of electric furnaces, but it announced in May that it would halve that amount to ¥150 billion.

The Japan Iron and Steel Federation compiled guidelines in October to evaluate the effectiveness of CO2 reduction methods. The government has established a framework to subsidize up to ¥449.9 billion of the research and development of hydrogen-based steelmaking technology, but that figure seems to be far from enough for the industry.

“Market creation is the most important thing in terms of recovering investments,” said Tadashi Imai, chairman of the federation and president of Nippon Steel.

Top Articles in Business

-

Prudential Life Insurance Plans to Fully Compensate for Damages Caused by Fraudulent Actions Without Waiting for Third-Party Committee Review

-

Japan, U.S. Name 3 Inaugural Investment Projects; Reached Agreement After Considerable Difficulty

-

Japan’s Major Real Estate Firms Expanding Overseas Businesses to Secure Future Growth, Focusing on Europe, U.S., Asia

-

SoftBank Launches AI Service for Call Centers That Converts Harsh Customer Voices into Softer Voices

-

Green Tea Exports Hit Record High in 2025 Amid Growing Demand, Likely to Be Driving Force Behind Govt Export Target

JN ACCESS RANKING

-

Producer Behind Pop Group XG Arrested for Cocaine Possession

-

Japan PM Takaichi’s Cabinet Resigns en Masse

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo Station

-

Israeli Ambassador to Japan Speaks about Japan’s Role in the Reconstruction of Gaza

-

Videos Plagiarized, Reposted with False Subtitles Claiming ‘Ryukyu Belongs to China’; Anti-China False Information Also Posted in Japan