An employee of Chiyoda Industries Co. in Ota, Gunma Prefecture, produces shift levers on Oct. 23. The parts will become unnecessary once electric vehicles become more common.

The Yomiuri Shimbun

13:08 JST, November 29, 2020

This is the fourth installment of a series exploring ways the auto industry plans to survive in the novel coronavirus era.

***

“It feels like I’m going through a long, dark tunnel,” said the head of an auto parts maker in Ota, Gunma Prefecture.

Orders fell 30% at his company, forcing him to take out loans totaling about 100 million yen. His business was hit by the novel coronavirus pandemic not long after he had finally paid off a 30 million yen loan he took out in the wake of the collapse of U.S. investment bank Lehman Brothers. He said the company would not hire new graduates next spring.

According to the Economy, Trade and Industry Ministry’s Monthly Report of Current Production Statistics for September, auto parts sales decreased by 1.5% compared to the same month a year earlier. However, it seems as if the business performance of parts makers is going to improve faster than expected as new vehicle sales are on an upward trend.

But this trend does not affect small and midsize parts makers. When a company of that size is hit by a financial crisis, it is difficult to recover from the blow. More than a few companies will be forced to cut jobs before their earnings begin to recover.

As of Thursday, at least 10 auto parts makers have offered buyouts, looking to cut 2,500 employees in total, according to Tokyo Shoko Research Ltd. At Mitsuba Corp. based in Kiryu, Gunma Prefecture, about 550 employees, including those of its group companies, accepted buyouts as the company’s earnings have been falling since before the pandemic.

“Many parts manufacturers were already close to the edge [before the pandemic], but now with the coronavirus, many have been pushed off,” said Koichi Sugimoto, senior analyst at Mitsubishi UFJ Morgan Stanley Securities Co.

Impact on local economies

The automobile industry has a large base. About 700,000 employees are involved in manufacturing auto parts nationwide, according to Japan Automobile Manufacturers Association Inc. and other sources. The loss of jobs at auto parts makers will inevitably have a negative impact on personal consumption and a considerable effect on the country’s overall economic recovery.

Sanden Holdings Co., based in Isesaki, Gunma Prefecture, applied for alternative dispute resolution (ADR) procedures for business revitalization, a type of private restructuring, in late June and is currently discussing ways to rehabilitate its operations with financial institutions. Sanden is a major employer for the prefecture with 7,000 employees.

Takayuki Soga, chairman of the Federation of Gunma Prefectural Chambers of Commerce and Industry, said area businesses are “concerned about the impact on the local economy.”

Hiruta Kogyo Co. in Kasaoka, Okayama Prefecture, has had to lay off about 120 employees, about 10% of its workforce, and also reduced the number of interns abroad.

“I want to believe that demand will return in a few years,” said company Chairman Shinzo Hiruta.

War on 2 fronts

Parts manufacturers are under pressure to fight a war on two fronts: They have to face the transition to electric vehicles and deal with ongoing cost reductions.

A gasoline-powered car requires 30,000 parts, while an electric vehicle requires only 10,000 to 20,000.

Chiyoda Industries Co., based in Ota, Gunma Prefecture, mainly produces shift levers for gasoline-powered vehicles but is now mass-producing car window frames.

“Shift levers will no longer become necessary once EVs became popular,” President Toshimasa Nakamura said.

Musashi Seimitsu Industry Co., based in Toyohashi, Aichi Prefecture, aims to increase the production ratio of EV parts, such as gears, from the current 10% to 25% in a few years.

“We pour our management resources [into manufacturing parts for EVs] and will take a leading role in the new era,” President Hiroshi Otsuka said.

Most Read

Popular articles in the past 24 hours

-

Iran Situation: Japan Must Exert Diplomatic Efforts without Merel...

-

Measles Patient Visited Hospital in Bunkyo Ward, Tokyo, Metropoli...

-

2 Unpublished Early Novellas by Japan's Kenzaburo Oe Discovered, ...

-

Prime Minister Sanae Takaichi to Visit Fukushima Pref. on 15th An...

-

Takayama Among World's Top 10 Most Welcoming Cities for 2026; 2nd...

-

Pass Rate for Overseas Driver's License Conversion Test in Japan ...

-

Former Nomura Securities Employee Given 18-year Prison Sentence f...

-

Bank of Japan and Markets: High Oil Prices Increase Difficulty of...

Popular articles in the past week

-

Milano Cortina 2026: Japanese Gold Medalist Figure Skater Miura S...

-

Tokyo Spends Big on Children, Wins Over Parents

-

Japan’s Miura, Kihara Announce Withdrawal from Figure Skating Wor...

-

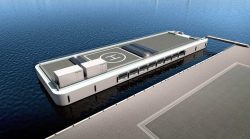

Yokohama to Test Out Renewable-Powered Offshore Floating Data Cen...

-

BOJ Keeping Eye on Economy and Takaichi's ‘Proactive Fiscal Polic...

-

Tokyo Measles Patient Traveled to Fukuoka Aboard JAL Planes; Susp...

-

South Korea Tightens Rules on Foreigners Buying Homes in Seoul Me...

-

Japan’s Takaichi Speaks on New U.S. Tariff in Upper House, Says P...

Popular articles in the past month

-

Producer Behind Pop Group XG Arrested for Cocaine Possession

-

Japan PM Takaichi’s Cabinet Resigns en Masse

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo...

-

Israeli Ambassador to Japan Speaks about Japan’s Role in the Reco...

-

Videos Plagiarized, Reposted with False Subtitles Claiming ‘Ryuky...

-

Prudential Life Insurance Plans to Fully Compensate for Damages C...

-

Woman with Measles Visited Hospital in Tokyo Multiple Times Befor...

-

iPS Treatments Pass Key Milestone, but Broader Applications Far f...

Top Articles in Society

-

Producer Behind Pop Group XG Arrested for Cocaine Possession

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo Station

-

Woman with Measles Visited Hospital in Tokyo Multiple Times Before Being Diagnosed with Disease

-

Bus Carrying 40 Passengers Catches Fire on Chuo Expressway; All Evacuate Safely

-

Tokyo Skytree’s Elevator Stops, Trapping 20 People; All Rescued (Update 1)

JN ACCESS RANKING

-

Producer Behind Pop Group XG Arrested for Cocaine Possession

-

Japan PM Takaichi’s Cabinet Resigns en Masse

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo Station

-

Israeli Ambassador to Japan Speaks about Japan’s Role in the Reconstruction of Gaza

-

Videos Plagiarized, Reposted with False Subtitles Claiming ‘Ryukyu Belongs to China’; Anti-China False Information Also Posted in Japan