Fukushima N-plant Decommissioning Work Enters New Stage; Challenge of Removing Debris Plain to See

The upper section of the No. 1 reactor’s steel frame is exposed at the Fukushima No. 1 nuclear power plant.

17:07 JST, December 16, 2024

I visited Tokyo Electric Power Company Holdings Inc.’s Fukushima No. 1 nuclear power plant for the first time in about a year and a half. The plant was the site of a nuclear accident caused by the 2011 Great East Japan Earthquake and tsunami.

On Nov. 20, I was able to see the exterior of the Nos. 1 to 4 reactors up close – including the No. 2 reactor, where the first successful retrieval of fuel debris had taken place on Nov. 7. I also entered the No. 5 reactor and even crouched directly underneath its reactor pressure vessel. At the plant, preparations are underway for the full-scale retrieval of fuel debris, which is the biggest challenge in the decommissioning process.

A bus route runs along the top of the seawall completed in March on the seaward side of the Nos. 1 to 4 reactors. The seawall is about 1 kilometer long and stands between 13.5 and 16 meters above sea level. It is about 5 meters wide at the top, and workers are transported to and from the plant using the road.

I got off the bus on the south side of the No. 4 reactor and walked north. I was wearing a helmet, mask and gloves, but not specialist protective clothing. On the way, I saw a cluster of pipes covered in frost. The TEPCO staff member accompanying me explained that “a calcium chloride solution is used to freeze the ground.” This solution is transported through the pipes and creates a barrier to keep groundwater away from the Nos. 1 to 4 reactor buildings and the sources of contamination.

-

The No. 4 reactor is completely encapsulated.

-

The pipes through which a calcium chloride solution flows to create a barrier to prevent groundwater contamination.

-

Construction of the seawall was completed in March.

-

There is a tunnel at the base of the seawall to drain seawater in the event that a tsunami overflows it.

-

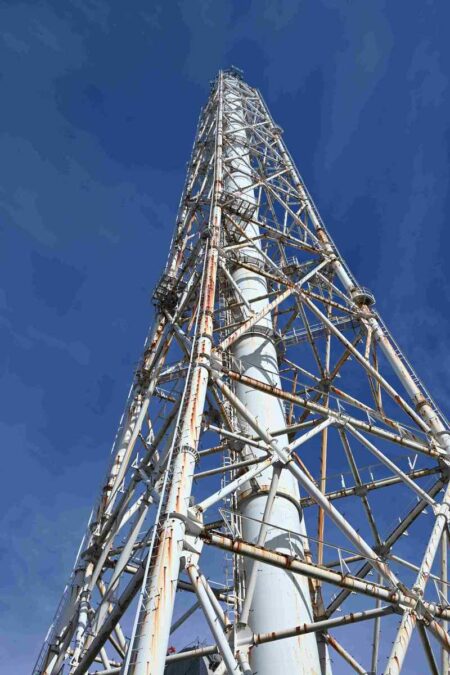

Exhaust tower located near the Nos. 3 and 4 reactors

-

The top section of the exhaust tower is now located near the observation deck overlooking the Nos. 1 to 4 reactors.

Towering near the cluster of pipes was the No. 4 reactor building. Unlike Nos. 1 to 3, the No. 4 reactor was not in operation at the time of the accident, as it was undergoing a routine inspection, and so did not undergo a core meltdown. However, hydrogen flowed into the building from the neighboring No. 3 reactor, causing the building to explode, sustaining significant damage. The building was enclosed by a cover and its1,535 spent nuclear fuel rods have been removed.

The building to the north houses the No. 3 reactor, where a domed roof cover reminiscent of a roll cake has been installed. The removal of its 566 spent nuclear fuel rods was completed in 2021, and inside the cover, there are cranes and other equipment.

-

The No. 2 reactor, where construction work is continuing on the upper part of the building

-

The No. 2 reactor, the first to have some nuclear fuel debris successfully retrieved.

-

The No. 2 reactor, the first to have some nuclear fuel debris successfully retrieved.

-

Removal of spent nuclear fuel rods has been completed at the No. 3 reactor.

-

Removal of spent nuclear fuel rods has been completed at the No. 3 reactor.

Going north again, I saw the No. 2 reactor and the entrance where the retrieval equipment was used. At the time of the accident, the hydrogen explosion at the No. 1 reactor caused the No. 2 reactor building’s blowout panel to open and the hydrogen to flow outwards, so there was no explosion, but the radiation level inside remains high. There are still 615 spent nuclear fuel rods inside. At present, work is underway to install equipment to enable decontamination work and the removal of the spent fuel rods.

While walking between the No. 2 and No. 1 reactors, I passed near the exhaust tower and the dosimeter I was wearing beeped loudly. It is designed to beep every time I received a radiation dose of 20 microsieverts – the maximum amount of radiation I was allowed to be exposed to during the day was set at 100 microsieverts.

-

The upper section of the No. 1 reactor as seen from the north

-

The upper section of the No. 1 reactor’s steel frame is exposed at the Fukushima No. 1 nuclear power plant.

-

The upper section of the No. 1 reactor’s steel frame is exposed at the Fukushima No. 1 nuclear power plant.

-

The former administrative building, which remains as it was at the time of the disaster.

The steel frame at the top of the No. 1 reactor was exposed. Work was in full swing to install a cover over the roof and construction materials were being placed on the ground by busy workers. There are 392 spent nuclear fuel rods inside the No. 1 reactor.

Inside a containment vessel

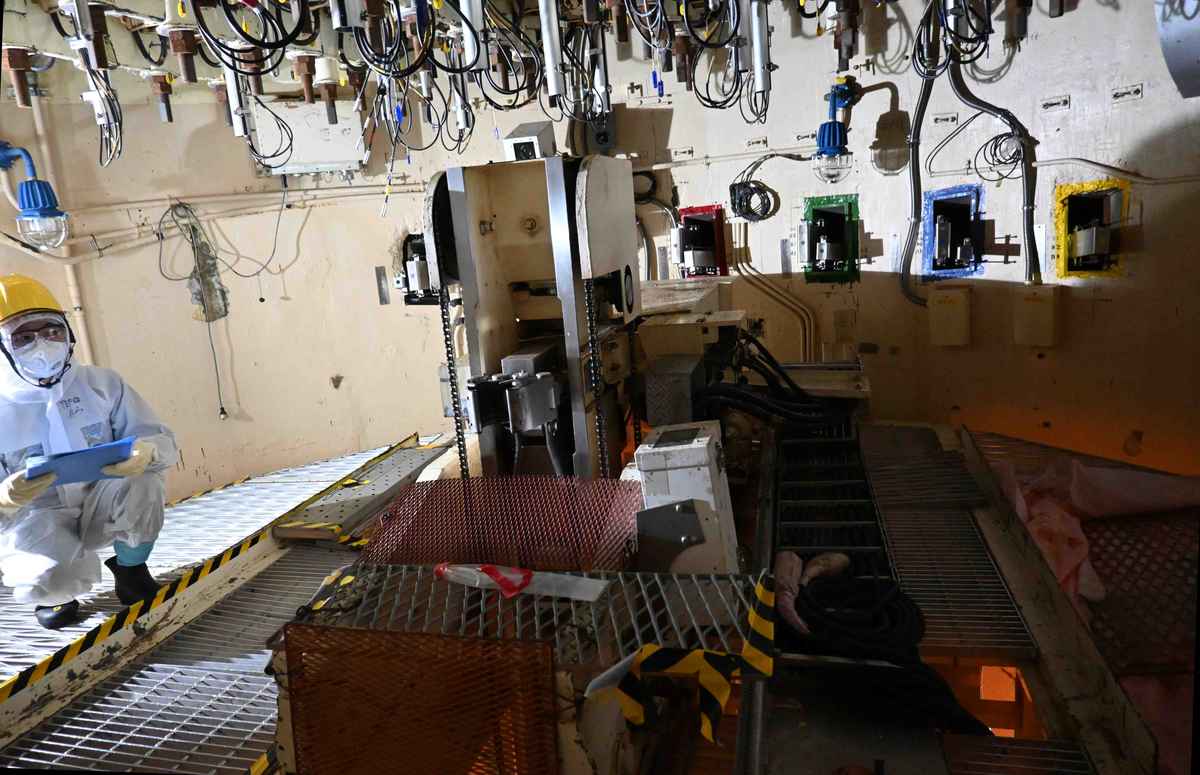

The area underneath the reactor core is cramped, and various pieces of equipment are hanging overhead, so you can’t stand up straight.

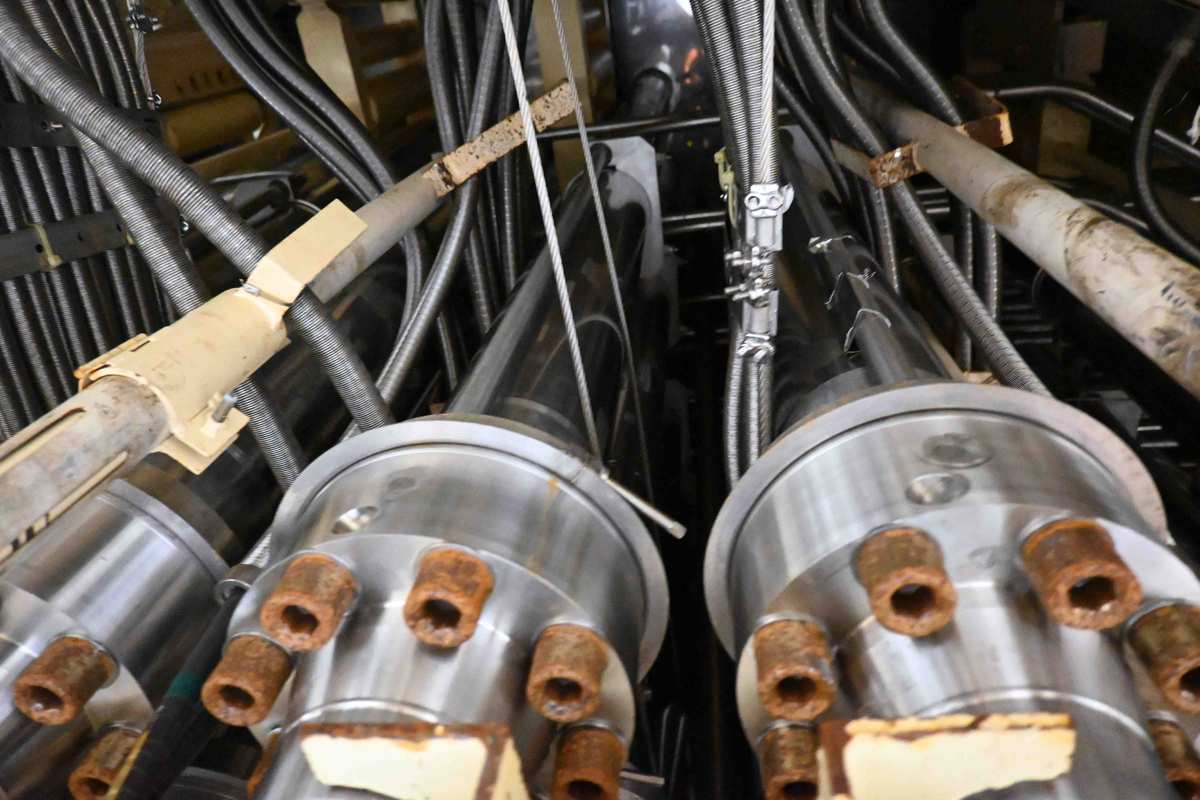

Both the No. 5 and No. 6 reactors are located a short distance north of the other four. During the earthquake, the No. 5 reactor was not in operation due to a routine inspection and did not lose power, so it was largely unaffected. It has the same structure as No. 2 and has therefore been used to prepare for the debris retrieval.

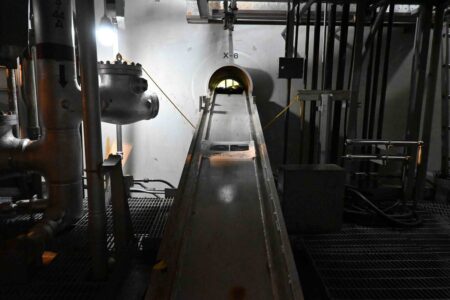

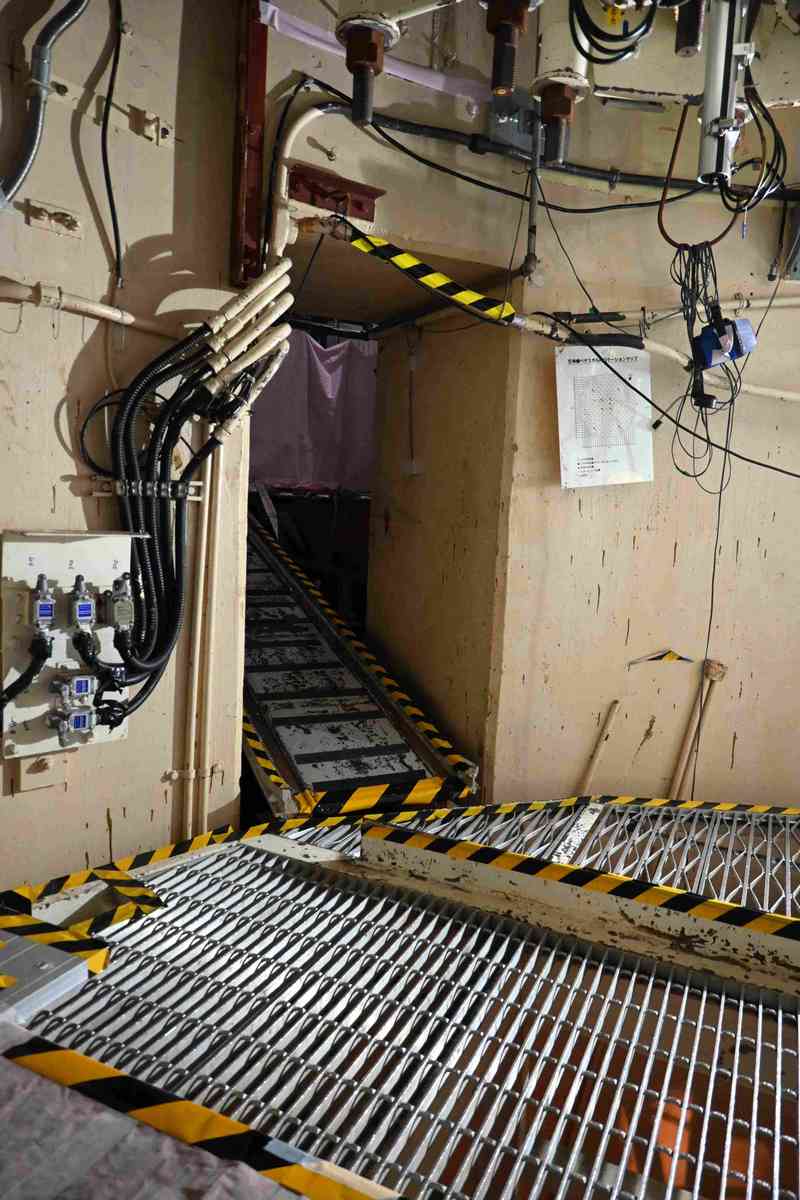

There is a hatch into the containment vessel that houses the reactor pressure vessel through which equipment can be transported during maintenance. It is 55 centimeters wide. During the retrieval of debris from the No. 2 reactor, a device was placed through the hatch above a rail that extended like a slide to directly beneath the pressure vessel. The tip of the device was fitted with a camera and a gripper and was lowered toward the bottom of the containment vessel, where it collected a pebble-like piece of debris.

-

The entrance to the No. 5 reactor’s containment vessel.

-

The hatch in the No. 5 reactor’s containment vessel

-

The hatch as seen from inside the containment vessel. A slide-like rail extends down.

-

The hatch as seen from inside the containment vessel. A slide-like rail extends down.

-

The slide continues further below the reactor core to the right.

-

View of the exit from the area directly below the reactor core

-

Looking up inside the reactor core, I couldn’t see the reactor pressure vessel.

-

Devices hanging overhead directly below the reactor core

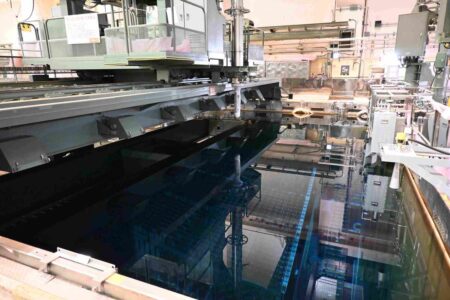

Before entering the containment vessel, I donned a protective suit and put on three pairs of socks at the entrance, as the radiation level was high. After entering, I changed my shoes again and bent down to go through the narrow entrance leading directly below the reactor core. The cylindrical interior was cramped, no more than 10 square meters. There were so many devices protruding above my head, such as the ones that move the control rods and the instruments that monitor the number of neutrons generated, that I couldn’t stand up. Looking down through the wire mesh floor, I could see the bottom about three meters below.

In the No. 2 reactor, the work was carried out just by the light of the remote-controlled device. Nuclear fuel inside the reactor melted along with pieces of equipment, forming a clay-like mixture along the bottom with pebble-like pieces of debris lying on top. Crouching inside the No. 5 reactor, the difficulty of the debris retrieval project became evident.

-

Fukushima No. 1 nuclear power plant’s No. 5 reactor (Courtesy of TEPCO)

-

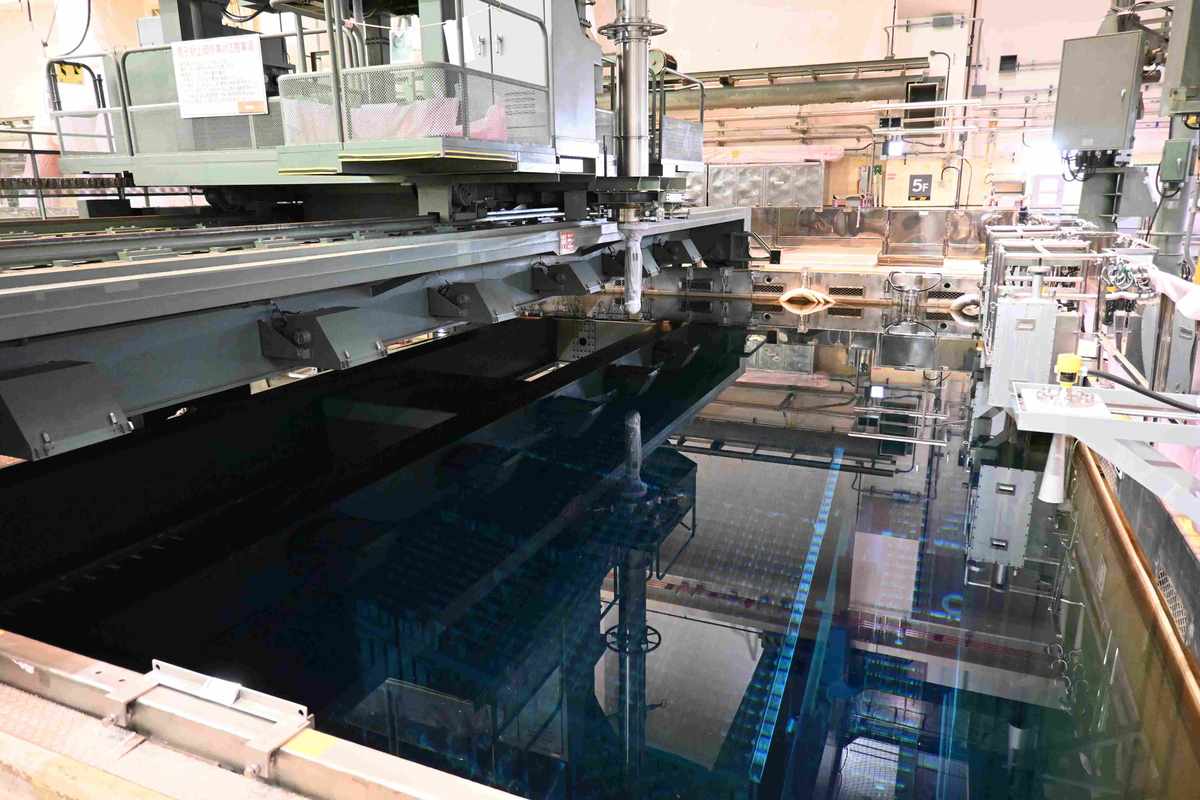

The pool in the No. 5 reactor where spent nuclear fuel rods are still stored.

-

A machine used to attach and remove the lid of a nuclear reactor

-

A concrete cover on top of the No. 5 reactor

The retrieved piece of debris will be analyzed at four research facilities, including the Japan Atomic Energy Agency’s Oarai Nuclear Engineering Research Institute in Ibaraki Prefecture. The results will be used to plan future retrieval operations. TEPCO plans to retrieve the fuel debris using the telescopic device again, as well as a robotic arm that is currently being designed. By repeatedly retrieving and analyzing small pieces of debris, they will work on a plan to expand the scale of retrieval, while also considering the engineering methods needed for each reactor.

The successful trial retrieval means that the decommissioning work has entered the third phase. The medium- to long-term roadmap, which was revised in December 2019, defines the first phase as “the period until spent fuel rod removal begins” and the second phase as “the period until fuel debris retrieval begins.” The third phase, which was scheduled to begin in December 2021, is defined as “the period until decommissioning is completed.” This phase began almost three years behind the roadmap. The target date for completing the decommissioning process, including the dismantling of the buildings and the disposal of the waste, is 2051.

The path ahead appears to be a long one.

Top Articles in JN Specialities

-

Tokyo University of the Arts Now Offering Free Guided Tour of New Storage Building, Completed in 2024

-

The Japan News / Weekly Edition (1/16-1/22)

-

The Japan News / Weekly Edition (1/30-2/5)

-

The Japan News / Weekly Edition (1/23-1/29)

-

Prevent Accidents When Removing Snow from Roofs; Always Use Proper Gear and Follow Safety Precautions

JN ACCESS RANKING

-

Univ. in Japan, Tokyo-Based Startup to Develop Satellite for Disaster Prevention Measures, Bears

-

JAL, ANA Cancel Flights During 3-day Holiday Weekend due to Blizzard

-

Japan Institute to Use Domestic Commercial Optical Lattice Clock to Set Japan Standard Time

-

China Eyes Rare Earth Foothold in Malaysia to Maintain Dominance, Counter Japan, U.S.

-

Japan, Qatar Ministers Agree on Need for Stable Energy Supplies; Motegi, Qatari Prime Minister Al-Thani Affirm Commitment to Cooperation