Japan’s Sake Breweries Enter Digital Era with Production Aid; Optimizes Timing of Key Steps of Process

Staff member Miwa Goto, right, shows a spreadsheet of data input into the digital tool to Mizutani Shuzo President Masao Mizutani at the brewery in Aisai, Aichi Prefecture.

1:00 JST, September 19, 2024

At Mizutani Shuzo, a sake brewery in Aichi Prefecture that dates back to the late Edo period, Miwa Goto opens a spreadsheet on her computer and inputs the alcohol content of the fermented mash, the amount of water added and other data.

Immediately, a graph appears indicating the progress of the fermentation process.

Mizutani Shuzo is among the growing number of sake breweries using a digital tool developed by the Nagoya Regional Taxation Bureau to automatically calculate the degree of fermentation of sake and present the data in graph form.

The tool, named “Moromi-eru” — for “moromi,” the fermented mash that is central to the process, and “eru,” to cheer on or support — uses digital technology to assist workers in breweries who through the centuries have had to rely on rule of thumb or individual instincts. The aim is to support the breweries to maintain quality and preserve the sake culture.

Japanese sake is produced by creating the moromi from rice, koji mold and water, then squeezing out the liquid. The fermentation process can be altered through the amount of water added, the temperature and other factors, and the timing of the squeezing affects the final product.

Each sake brewery keeps a daily log of the water added and other data. Inputting the numbers into the digital tool allows for the degree of fermentation to be automatically calculated and indicated on a graph. This serves as a visual aid for deciding when to squeeze the moromi, no longer leaving it up to personal instinct.

For reference, the tool also shows the degree of fermentation for past winners of the gold prizes at the annual Japan Sake Awards.

The brewery at Mizutani Shuzo, located in the city of Aisai, suffered a devastating fire in May this year that completely burned down the building and caused the majority of its brewing logbooks to be lost.

This season, the company plans to resume operations by leasing space at another brewery. In preparation, it is inputting data that wasn’t lost in the fire in the digital tool.

“It will make it easier to reproduce the sake that we made in the past,” Goto, 26, said.

The digital tool made its full-fledged debut in January last year. According to the tax bureau, it has been provided to at least 40 sake breweries in the Tokai region, and others in the Tohoku region and elsewhere have expressed interest.

At the Fukui Syuzo brewery in Toyohashi, Aichi Prefecture, the tool has helped shorten work hours.

“The tool’s data on degree of fermentation provides support for my own instincts based on my experience, which makes it easier to determine when to do the squeezing,” a 67-year-old sake brewer master said.

Shortage of brewers

In Japan, administration related to alcoholic drinks is handled by the national tax authorities. According to National Tax Agency statistics, the number of the nation’s sake breweries fell about 40% in the past 30 years, and consumption of seishu (refined sake) has decreased by 70% in that span.

This trend can be attributed to the popularity of cheaper alcoholic beverages such as beer and beer-like products, as well as the aging of brewer masters, called toji, and the inability to find successors to run the breweries.

The Nagoya tax bureau hopes that the tool will help oversee sake production and maintain quality to a certain degree, which will lead to improved operational efficiency and help ease the labor shortage.

“The individual instincts and experience of the toji are of course important,” said Kenichiro Tajima, chief of the bureau’s Office of Analysis and Brewing Technology. “The tool helps produce a stable supply of good sake. Sake is going to make a comeback.”

Top Articles in Business

-

Prudential Life Insurance Plans to Fully Compensate for Damages Caused by Fraudulent Actions Without Waiting for Third-Party Committee Review

-

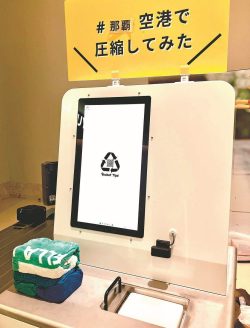

Narita Airport, Startup in Japan Demonstrate Machine to Compress Clothes for Tourists to Prevent People from Abandoning Suitcases

-

Japan, U.S. Name 3 Inaugural Investment Projects; Reached Agreement After Considerable Difficulty

-

Toyota Motor Group Firm to Sell Clean Energy Greenhouses for Strawberries

-

SoftBank Launches AI Service for Call Centers That Converts Harsh Customer Voices into Softer Voices

JN ACCESS RANKING

-

Japan PM Takaichi’s Cabinet Resigns en Masse

-

Japan Institute to Use Domestic Commercial Optical Lattice Clock to Set Japan Standard Time

-

Israeli Ambassador to Japan Speaks about Japan’s Role in the Reconstruction of Gaza

-

Man Infected with Measles Reportedly Dined at Restaurant in Tokyo Station

-

Videos Plagiarized, Reposted with False Subtitles Claiming ‘Ryukyu Belongs to China’; Anti-China False Information Also Posted in Japan